Air Delivery System Application

In modern industrial and commercial applications, pneumatic conveying systems are an important method of material transport, widely used in industries such as manufacturing, healthcare, logistics, electronics, and food processing. These systems are typically used to transport lightweight materials, liquids, or gases from one location to another, improving efficiency and reducing labor costs. Due to its transparency, durability, and workability, acrylic tubing has become an ideal choice for various pneumatic conveying systems, offering a transparent, reliable, and efficient solution for many industries.

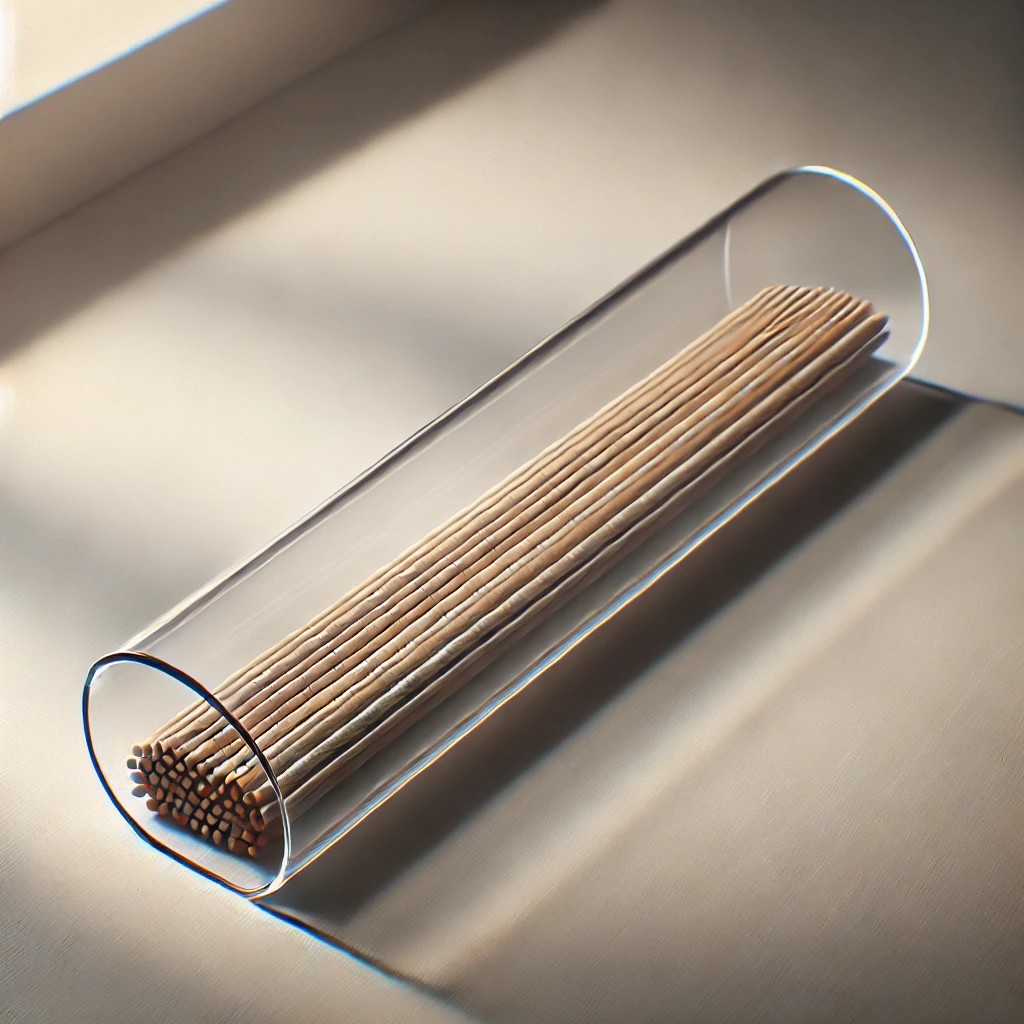

AI-Generated, for reference only.

1. Applications in Material Transport

2. Pneumatic Systems in Cleanrooms and Laboratories

Acrylic tubes are widely used in pneumatic systems within environments requiring high cleanliness, such as cleanrooms and laboratories, for transporting clean gases or sensitive materials. Acrylic’s excellent chemical resistance and anti-contamination properties prevent external pollutants from entering the system, ensuring high levels of cleanliness during the transport process. Additionally, acrylic tubes are easy to clean and disinfect, helping maintain the long-term stable operation of these systems.

3. Logistics and Package Transport Systems

In modern logistics and package handling centers, acrylic tubes are used to construct automated package transport systems. These systems typically use compressed air or vacuum technology to rapidly move packages from one area to another through acrylic tubes. The transparency of acrylic tubes allows logistics operators to easily monitor the package transfer process, ensuring accurate sorting and delivery. Furthermore, the lightweight and high-strength characteristics of acrylic tubes make them well-suited for high-speed operations, reducing maintenance costs.

4. Medical and Pharmaceutical Delivery Systems

Acrylic tubes also play a crucial role in pneumatic systems used in the medical and pharmaceutical fields. These systems are often utilized for transporting medications, samples, or other medical items within healthcare facilities. Acrylic tubes provide a highly clean transport channel, and their transparency allows medical staff to observe and confirm the status of transported items, thereby enhancing the safety and reliability of the delivery process.

Acrylic Tubes in Pneumatic Systems Key Advantages

Transparency: The transparency of acrylic tubes allows operators to monitor the transport process in real-time, ensuring the system runs safely and efficiently.

Durability: Acrylic material offers excellent impact resistance and wear resistance, capable of withstanding the high-speed operations and high-pressure environments in pneumatic systems.

Lightweight: Acrylic tubes are lightweight, making them easy to install and maintain, and suitable for use in various complex environments.

Workability: Acrylic tubes can be custom-processed to create pipes of different sizes and shapes, tailored to meet the specific application requirements of various pneumatic systems.

The application of acrylic tubes in pneumatic systems demonstrates their versatility and efficiency. Whether in industrial production, logistics transportation, or medical delivery, acrylic tubes provide reliable pneumatic solutions across industries due to their outstanding performance. As technology continues to advance, the range of applications for acrylic tubes in pneumatic systems will expand, contributing to the development of modern automated transport systems.

Related FAQ

Is acrylic environmentally friendly?

SMEACRYLIC packaging

What is Acrylic (PMMA) ?

Acrylic VS. Glass

Storage- -Application of acrylic tube

Polycarbonate (PC) Extrusion Manufacturers 10 Q&A

Related Applications