White Acrylic Sheet

SME has many years of experience in the LED lighting market through professional optical structure design and composite diffuser technology. Our one-stop service, from formula design, mixing and granulation, pressing board production to cutting and packaging, provides the best quality optical materials and customer experience.

Description

| Model | Material | Standard Size (mm) | Thickness (mm) | T/T% | HZ% |

| SL-A1290 | PMMA | 1200 x 1200 | 1.5 | 88 | 99 |

| SL-A1280 | 1200 x 1200 | 1.5 | 79 | 99 | |

| SL-H1285W | Hi-Impact PMMA | 1220 x 1830 | 1.8 | 86 | 99 |

| SL-H1275W | 1280 x 1280 | 2 | 68 | 99 | |

| SL-S1290 | PS | 1200 x 1200 | 1.5 | 91 | 99 |

| SL-S1380 | 1200 x 1200 | 1.5 | 83 | 99 | |

| SL-P36003 | 1200 x 1200 | 1.5 | 57 | 99 | |

| SL-P26002 | 1200 x 1200 | 1.2 | 56 | 99 |

Note:

T/T: Total light transmittance

HZ: Haze

White Acrylic Sheet Features

• Own material formula.

• Composite material extrusion.

• Double-sided structure design.

• Excellent optical transmission characteristics.

• White Acrylic Sheet is Good dimensional stability.

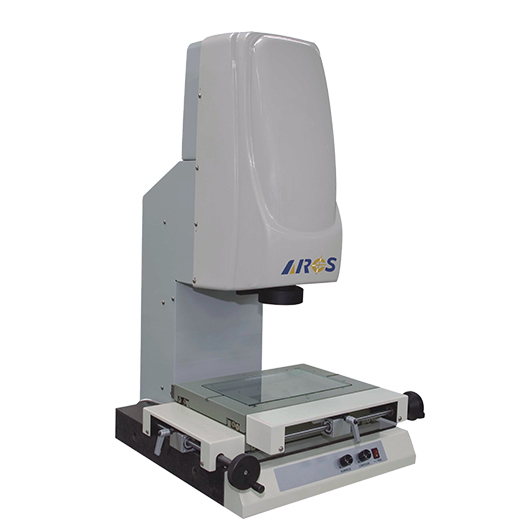

- Cutting: Cutting according to the size required by customers, the precision tolerance can reach ±0.5mm

- Polishing: Treat the acrylic surface with a diamond polishing machine to make it smooth and translucent.

- Drilling: Drilling according to customer's requirements, and it is matched with customer's sample kit.

- Bending: Bending according to customer's requirements, heating the acrylic tube, and then bending with jigs.

- Chamfering: The edge of the acrylic pipe is chamfered to reduce sharp edges.

- Printing: Print patterns, words or images onto the acrylic surface to achieve personalized decorative effects.

- Laser cutting: Using high-power laser beams for precise cutting can achieve diverse cutting needs.

- Assembly: process and assemble with the accessories required by customers to complete one continuous line service.

- SMEACRYLIC® is a Taiwan based manufacturer which was founded in year 1980, a Professional Manufacturer in Extrusion Technology.

- We specializes in extruding various kinds of plastic Profiles, Tubes, Rods and Sheets which be used in displays, decorations, lighting, illuminated advertising, architectures and a lot more applications.

- Approximately 90% of our products are exported to over 40 countries worldwide including numerous well-known brands. Over the years, we have expanded to become the market leader in extrusion field in Asia.

We insist on using 100% virgin materials.

We insist on using international branded raw materials (Sumipex, Mitsubishi, Evonik)

We insist on keeping sample records of raw materials, all raw materials are traceable.

- We developed on line catalogue for our customers.

- Stock system always offers efficient prompt delivery.

- Samples available for most of our products.

- Our home-made moulds offer fast and precision work to ensure customers' satisfaction.

- Efficient ISO-9001 managing system ensures quality stability.

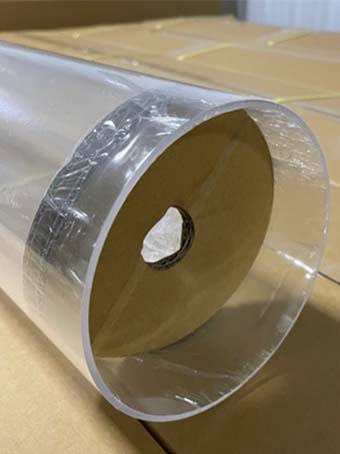

- Exclusive shrink film packaging slows down the water absorption of acrylic

- Giving you a good cutting experience

- Effectively avoid scratches on acrylic tube surface during cutting

- Small tubes are bundled to increase the strength and are not easy to break

- Bubble Wrap protects the tubes druing transportation

- Carton protection, convenient for warehouse management

- Square package, maximizing the storage capacity of the warehouse