Acrylic Sheet Maintenance and Storage Guidelines

Acrylic Sheet Maintenance and Storage Guidelines

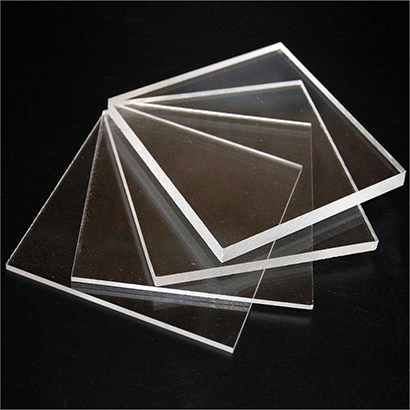

To ensure the prolonged use and optimal condition of acrylic sheets, proper maintenance and storage are crucial. Acrylic, being a high-quality transparent plastic material, finds wide applications across various

fields. However, its sensitivity to environmental factors and handling necessitates special care. By adopting correct maintenance and storage practices, we can ensure that acrylic sheets maintain clarity, durability, and superior performance over time. The

following are some recommendations aimed at providing guidelines for the maintenance and storage of acrylic sheets to maximize their potential benefits.

Cleaning: When cleaning acrylic, use a mild soap or detergent with lukewarm water and a soft cloth or sponge. Gently wipe the surface to avoid scratches, avoiding abrasive materials that can reduce

clarity. For a streak-free finish, use a microfiber cloth.

Avoid Harsh Chemicals: While acrylic sheets are generally corrosion-resistant, their tolerance to specific chemicals depends on the material's quality and manufacturing process. Acrylic exhibits

good resistance to water, acids, and bases. However, exposure to strong, corrosive chemicals such as solvents, acids, or bases may have limitations. It is advisable to conduct material compatibility tests before using chemicals that may potentially damage

acrylic.

Scratch Prevention: While acrylic serves as an alternative to glass, it has a lower hardness compared to glass. To maintain the clear surface of acrylic sheets and prevent scratches, it is essential

to be cautious. Typically, acrylic sheets come with a protective film to avoid scratches and the attachment of dirt. It is recommended to perform operations and processing with the protective film in place, ensuring that the protective paper (film) is only

removed at the end. This practice helps preserve the perfection of acrylic sheets.

High-Temperature Limit: Acrylic has a high-temperature limit of approximately 70°C. Prolonged exposure to high temperatures can cause acrylic to soften, leading to loss of shape stability. Avoid

exposing acrylic to high temperatures to prevent deformation or damage. For applications requiring high-temperature resistance, consider materials like polycarbonate (PC) or polytetrafluoroethylene (PTFE), known for better stability at elevated temperatures.

Storage: Ensure even weight distribution to avoid imbalance and reduce the risk of deformation. Control stacking height carefully to minimize pressure on acrylic sheets. When stored horizontally,

use a flat, level surface to prevent warping over time.

When stored vertically, ensure tight attachment of the entire board, maintaining a 10° inclination to prevent sagging. Additionally, keep the height below 30cm. Use

appropriate supports and fixing methods for stable stacking structure, such as brackets or frames, to prevent lateral movement or collapse.

Stacking acrylic sheets should

strictly avoid placing heavy objects on them, as acrylic is a relatively fragile material susceptible to deformation, scratches, or cracks under external pressure and weight. Stacking heavy items may lead to excessive pressure on the sheets, increasing the

risk of deformation and adversely affecting their appearance and performance.

Stacking acrylic sheets should

strictly avoid placing heavy objects on them, as acrylic is a relatively fragile material susceptible to deformation, scratches, or cracks under external pressure and weight. Stacking heavy items may lead to excessive pressure on the sheets, increasing the

risk of deformation and adversely affecting their appearance and performance.

Avoid Direct Sunlight: While acrylic boasts good weather resistance, it is strongly recommended to avoid exposing acrylic sheets to direct sunlight to ensure their quality and appearance remain undamaged. UV rays and intense light in sunlight can potentially

cause acrylic sheets to yellow and lose their gloss. Store acrylic sheets away from direct sunlight and extreme temperatures to prevent yellowing or degradation, preserving their original color and preventing deterioration.

Temperature and Humidity: When considering the use and storage of acrylic sheets, temperature and humidity are two crucial factors that require special attention. Acrylic sheets are highly sensitive

to changes in temperature and humidity. It is essential to maintain a stable and moderate level of temperature and humidity in the storage area. High humidity may result in condensation on the surface of acrylic sheets, while low humidity can make the material

brittle. To achieve and maintain stable humidity levels, the use of dehumidifiers or humidifiers can be considered, depending on specific needs.

Regular Inspection: Regularly inspecting stored acrylic sheets for signs of damage or degradation, following these recommended maintenance and storage guidelines, will help preserve the optical transparency and physical integrity of the acrylic sheets. Overall, through routine and thorough inspections, potential issues can be identified and addressed early on, ensuring that acrylic sheets maintain their superior appearance and performance over the long term.

Related Applications

.jpg)

.jpg)