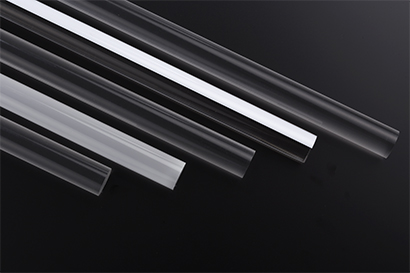

Inspection Equipment

Q: SMEACRYLIC's Inspection Equipment

The inspection SOP from the incoming of raw materials to the shipment of finished products, the inspection equipment is as follows, in line with the ISO9001 quality management system, to ensure that the products can meet the needs

of customers.

◆ Electronic vernier calipers, digital centimeters, electronic scales:Make sure the size and weight meet the tolerance requirements.

◆ Illuminometer:It has a multi-probe network to form a multi-point

illumination measurement system, which can accurately and efficiently measure the illumination of acrylic light guide strips. The measurable parameters include plane illumination (horizontal illumination, vertical illumination), illumination difference, illumination

ratio, integral Illuminance, average illuminance, etc.

◆ Handheld Spectral Color Light Meter:It is a multi-functional and easy-to-operate spectrophotometer, which can be accurately measured without a computer. It can measure the illuminance, color temperature, CRI,

spectrogram, and light measurement related data of acrylic light guide strips to meet customer requirements. Product inspection standards.

◆ Laser measuring instrument:Measuring range: 4x4mm or 13x13mm, measurable diameter: 0.03~10mm, repeatability: up to ± 0.03 µm, in the production process of the light guide strip, with a laser measuring instrument to measure the size per second, high-precision measurement The measurement system can ensure that the size of each batch of light guide bars can meet customer needs.

◆ Moisture Analyzer:After the raw material particles are baked, a moisture analyzer is used to detect the moisture content of the acrylic.

◆ Plastic Melt Index Tester:Each batch of raw materials entering the factory will check the

MI value to ensure that the quality and stability of acrylic raw materials are in line with the data provided by the original factory.

According to ASTM D1238 standard temperature and load, measure the flow quality and volume of acrylic raw material particles in a certain time in the molten state, and calculate the melt volume flow rate (MVR) and melt gravimetric flow rate (MFR).

◆ Programmable constant humidity and constant temperature testing machine:Acrylic

has good weather resistance, but physical changes may still occur in the face of temperature and humidity in various countries, so this device can simulate acrylic. After testing at different temperatures and humidity, Whether there will be yellowing and qualitative

change to evaluate the degree of weather resistance under various environmental conditions.

◆ Alcohol Stress Test:All products produced by SME will be tested for stress. We will test the acrylic

products in production by immersing them in 95 degree alcohol for 5 minutes to ensure that the products will not be caused by residual stress, which may cause damage to the products during processing. Cracking or fogging phenomenon.

Related Applications

-1.jpg)